- An ISO 9001:2008, ISO 14001:2004 & OHSAS 18001:2007 certified facility with authorization for ASME U, U2, S, R, NB stamping

- IBR as well as CCOE/PESO approved Shop floor

- Equipped with design software like PV Elite (for the mechanical design of Pressure Vessels, Heat Exchanger, Mounded Bullets, Horton Spheres etc.) and drafting software such as AutoCAD 2015

- Total Area available is 10,950 Sqm having a covered Shed Area of 3,015 Sqm

- Industrial infrastructure & facilities available near factory are approved testing laboratories, trade test facilities, NDT facility, ancillary shop for precision machining, powder coating facility, galvanizing plant

Manufacturing Process Equipment:

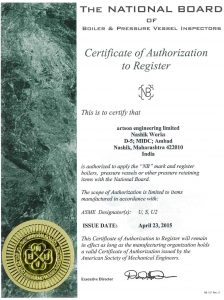

- ASME ‘U’, ‘U2’ & NB

- Stamp Pressure

- Vessels

- Heat Exchangers

- Columns

Our Capabilities at Nashik Unit:

- Tall Tower & Column

- Tanks

- Tubular Reactor, Limpet Coil Reactors

- Steam Drum

- Shell & Tube type Heat Exchanger

- Deaerator

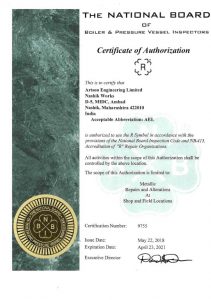

- ASME U, U2, NB, R, S coded Process equipment.

- LPG Bullets

- IBR Vessels & Explosion Cladded vessels

- Air Receivers & Process Equipment’s

- Cryogenic Tanks & Vessels, knock out drums

- Cold Stretched Vessels

- Stacks

- Floating Suction Assemblies, Skimmers, Dish ends

Factory Tour

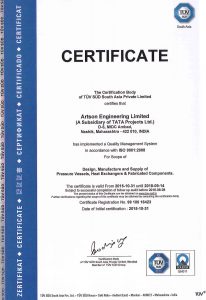

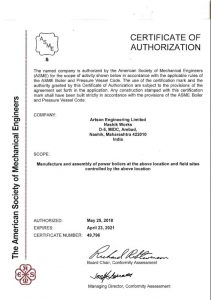

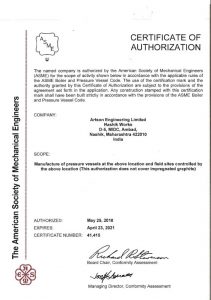

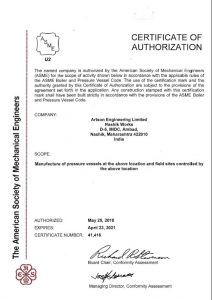

Certifications

- ISO 9001:2008 Certificate TUV

- ISO 14001:2004 Certificate TUV

- OHSAS 18001:2007 Certificate TUV

- ASME S STAMP

- ASME U STAMP

- ASME U2 STAMP

- CCOE CERTIFICATE

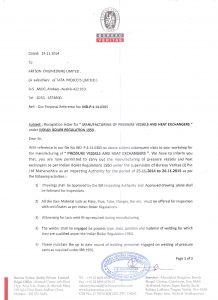

- IBR CERTIFICATE 2014 – 15 _1

- IBR CERTIFICATE 2014 – 15 _2

- NB CERTIFICATE_1

- R Stamp Certificate